Du plastique au cuir, en passant par le bois massif et même les produits synthétiques et à base de plantes, les constructeurs automobiles explorent en permanence les possibilités des matériaux d'intérieur.

Le cuir a longtemps été utilisé comme matériau pour les intérieurs de voitures de luxe et reste une « nécessité » pour de nombreux modèles haut de gamme. Cependant, ces dernières années, plusieurs marques automobiles promeuvent vigoureusement le développement d'alternatives au cuir, certaines marques ont même ou envisagent d'abandonner complètement l'utilisation de matériaux en cuir.

VOLVO a annoncé que d'ici 2030, l'entreprise abandonnera complètement la production de voitures en cuir animal et utilisera à la place des matériaux recyclables et respectueux de l'environnement.

Mercedes Benz, BMW, Land Rover, Bentley et plusieurs autres marques de voitures proposent depuis longtemps des intérieurs sans cuir et respectueux de l'environnement en option.

Tesla a déjà abandonné le cuir comme option intérieure, et Rivien, une autre start-up automobile américaine, s'apprête à lancer son pick-up R1T proposant uniquement des sièges en cuir vegan.

Avec le concept de protection des animaux et de protection de l'environnement profondément ancré dans l'esprit des gens, la mentalité des consommateurs a également changé, en particulier les jeunes consommateurs ne sont pas aussi favorables que par le passé au cuir animal, un nouveau choix de consommateur se forme tranquillement.

Le liège est l'une des étoiles montantes des intérieurs automobiles.

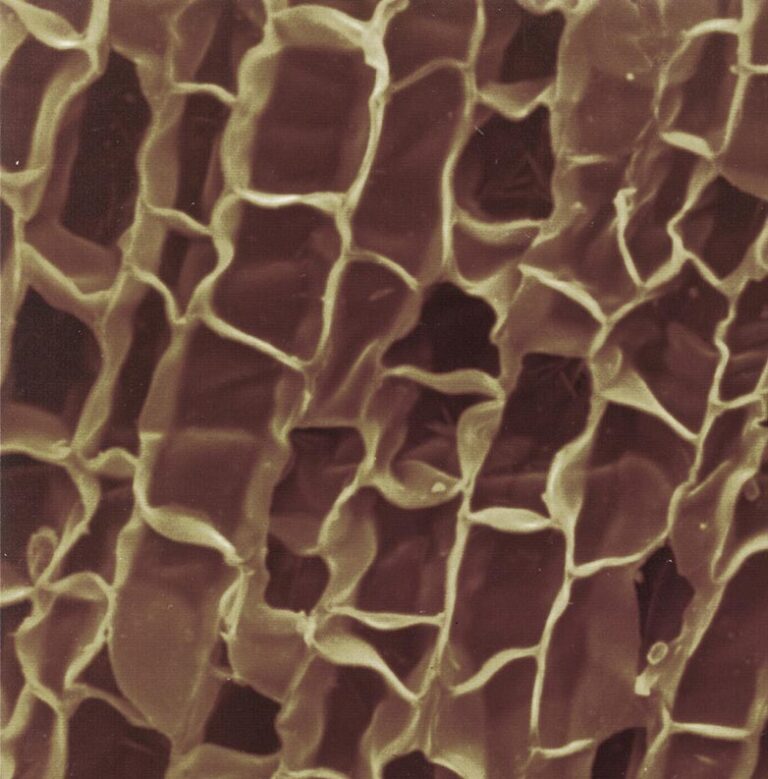

Le liège est une fibre naturelle du chêne-liège, formée par l'agglomération de cellules hexagonales qui contiennent à l'intérieur des gaz similaires à l'air. Les alvéoles sont recouvertes de liège et de lignine.

Le liège provient de l'écorce du chêne-liège portugais et est un Ressource renouvelable parce que l'arbre n'est pas abattu pour récolter le liège, il est simplement dépouillé de son écorce pour obtenir du liège, qui commencera à se régénérer et à absorber plus de dioxyde de carbone. Le chêne-liège a une durée de vie d'environ 300 ans, et le liège brut peut être récolté à plusieurs reprises dans des cycles de 8 à 9 ans, avec plus d'une douzaine de bandes d'écorce d'un seul arbre mature.

Les forêts de chênes-lièges absorbent 14 millions de tonnes de dioxyde de carbone chaque année, contribuant à ralentir le réchauffement climatique et à prévenir la désertification des terres. Il contribue à atténuer le réchauffement climatique, à réduire l'érosion des sols et à réguler le cycle de l'eau.

Chaque bouchon absorbe en moyenne 112 grammes de dioxyde de carbone.

Chaque tonne de liège absorbe 1,83 tonne de dioxyde de carbone

Fabriquer un bouchon de bouteille en plastique émet 10 fois plus de CO2 qu'un bouchon de liège.

La fabrication des bouchons à vis en aluminium émet 24 fois plus de CO2 que le liège.

Des études montrent que pour chaque tonne de liège produite, les forêts de chênes-lièges peuvent séquestrer jusqu'à 73 tonnes de CO2, contribuant ainsi à réduire le potentiel de réchauffement climatique.

Les composants intérieurs automobiles comprennent : les volants, les cloisons de cabine, les panneaux de porte intérieurs, les tableaux de bord, les couvercles d'airbag, les accoudoirs de siège, les tapis de sol, les poignées de porte intérieures, les porte-gobelets, les garnitures, les garnitures de toit, les pare-soleil, les dégivreurs de vitres latérales, les bacs utilitaires et les couvertures , des appendices insonorisants et d'autres composants.

Alors que les gens recherchent l'apparence et la puissance de la voiture, ils accordent également de plus en plus d'attention au design de l'intérieur. L'intérieur reflète non seulement la fonction de l'espace intérieur de la voiture, mais permet également aux passagers de se sentir à l'aise, faciles à contrôler, visuellement beaux, sains et sûrs, ainsi l'intérieur est devenu un champ de bataille important pour la compétition de différentes marques de voitures. aujourd'hui.

L'industrie automobile, en tant que l'une des plus grandes industries au monde, est au centre de cet effort. Le trafic routier est une source majeure de pollution, les voitures et les camions représentant près d'un cinquième de toutes les émissions américaines, et chaque gallon d'essence émet environ 24 livres de dioxyde de carbone et d'autres gaz à effet de serre. Environ 5 livres proviennent de l'extraction, de la production et de la livraison du carburant, tandis que la plupart des émissions de chaleur - plus de 19 livres par gallon - proviennent directement des gaz d'échappement des voitures.

Dans l'ensemble, le secteur des transports aux États-Unis, y compris les voitures, les camions, les avions, les trains, les navires et le fret, produit près de 30 % des émissions totales de réchauffement climatique aux États-Unis, plus que presque tous les autres secteurs.

Les chênes-lièges du Portugal - environ un tiers de la taille des forêts méditerranéennes de chênes-lièges - absorbent à eux seuls 4,8 millions tonnes de CO2 par an, ce qui, selon l'Environmental Protection Agency des États-Unis, équivaut aux émissions par 830 000 voitures particulières/an.

Dans la conversion d'un kilogramme de liège, 50 kilogrammes de CO2 sont absorbés par l'atmosphère. L'utilisation du liège est l'un des moyens d'atténuer efficacement l'effet de serre.

Le liège est l'un des nouveaux matériaux environnementaux les plus durables et directement efficaces disponibles.

La légèreté est également devenue l'une des directions de développement importantes des intérieurs automobiles. Il y a deux raisons à cela : d'une part, les réglementations en matière de consommation de carburant et d'émissions deviennent de plus en plus strictes, et la légèreté est l'un des principaux moyens d'économie d'énergie et de réduction des émissions. Selon les statistiques de l'industrie, on estime que si le poids de la voiture est réduit de 10 %, elle peut économiser 6 % à 8 % de carburant, réduire la consommation de carburant de 0,3 litre à 0,6 litre aux 100 kilomètres et réduire les émissions de dioxyde de carbone de 5 grammes-8 grammes; d'autre part, les composants intérieurs de la voiture peuvent être optimisés grâce à la structure, aux matériaux et à d'autres aspects pour réduire efficacement le poids, ce qui aide l'ensemble de la voiture à économiser de l'énergie et à réduire les émissions.

Le liège est si léger qu'il flotte réellement. Il y a environ 40 millions d'alvéoles dans chaque centimètre cube de liège, qui sont toutes remplies d'un mélange de gaz semblable à l'air. À propos 60% de la feuille de liège est constituée d'éléments gazeux. Cela explique son extraordinaire légèreté. Le liège ne pèse que 0.16 grammes par centimètre cube. Le poids est un indicateur important pour les intérieurs de voitures et la façon dont le liège présente d'excellents avantages physiques et est l'un des matériaux de choix pour les concepteurs.

Alors que de nombreux conducteurs préfèrent un véhicule bruyant, beaucoup préfèrent un environnement calme qui offre un trajet sans bruit et relaxant.

Le bruit de la route peut affecter votre expérience quotidienne de conduite d'une voiture, surtout si cela signifie que vous ne pouvez même pas tenir une conversation sans élever la voix.

Généralement, pour réduire le bruit intérieur, en plus des améliorations matérielles, les ingénieurs sont plus susceptibles d'augmenter le développement de la laine de mousse intérieure et du verre pour réduire le bruit à l'intérieur et à l'extérieur de la voiture, mais cela peut augmenter considérablement les coûts de production.

Le liège par centimètre cube de liège contient près de 40 millions de cellules, peut absorber efficacement le bruit. Le liège est un excellent réducteur de bruit. Il ne faut pas grand-chose pour obtenir une isolation phonique efficace avec du liège. Selon les découvertes, un bouchon de 3/32 pouces (seulement 3 mm) peut bloquer jusqu'à 10 décibels de son. C'est pourquoi il est souvent utilisé dans les studios d'enregistrement et les théâtres.

Pour les passionnés d'autoradio, c'est simplement un lieu de repos pour leurs âmes - laissez le monde extérieur me déranger, je suis dans le dialogue de la musique et de l'âme de la voiture. Entrer et sortir de la voiture sans se déranger.

Alors que l'industrie automobile continue d'accélérer l'itération, en particulier les véhicules électriques à énergie nouvelle, de plus en plus de composants électroniques de haute précision dans la voiture, ainsi que le risque accru de panne, en particulier la console centrale, plus de contacts humains, le problème de la génération d'électricité statique l'électricité est mise en évidence. De plus, les zones basses du pays, sujettes aux événements d'immersion de voitures, entraînent la mise au rebut des composants électroniques.

Pour cela, les produits en liège permettent de protéger l'équipement de la voiture. La surface antistatique du liège limite les possibilités d'absorption de la poussière et des toxines, ce qui en fait un excellent choix pour les personnes allergiques. Le liège a des propriétés antimicrobiennes naturelles qui garantissent une grande promesse dans l'aggravation de la moisissure, du mildiou, des termites et d'autres infestations d'insectes nuisibles.

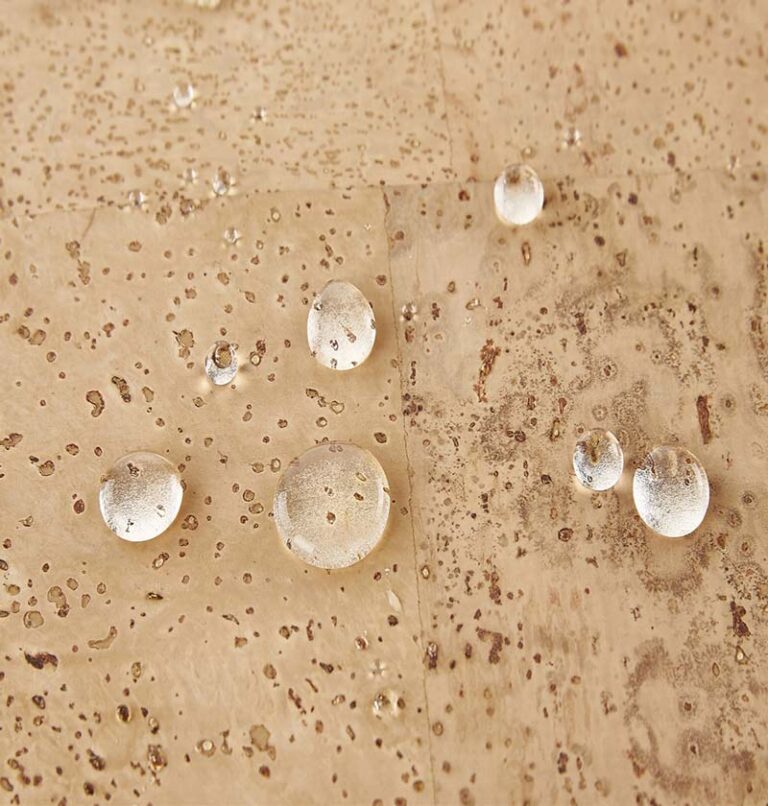

De plus, le liège est imperméable. Ce matériau contient des centaines de milliers de cellules par centimètre cube, et ces cellules contiennent également du liège, qui est une substance grasse naturelle. Par conséquent, il n'y a presque pas de rétention d'eau dans les parois cellulaires, ce qui explique parfaitement pourquoi le liège a des propriétés imperméables.

Cela garantit que votre équipement est complètement sûr même dans les conditions météorologiques les plus difficiles, grâce à leur résistance à l'humidité et leur imperméabilité aux liquides.

Aujourd'hui, avec l'augmentation progressive de la sensibilisation à la santé et le durcissement des normes d'évaluation des substances toxiques dans les voitures, la question de la qualité de l'air dans les voitures reçoit de plus en plus d'attention.

Cependant, au cours de la dernière décennie, le problème des odeurs dans la voiture a figuré parmi les dix principales plaintes concernant la qualité automobile, et les consommateurs accordent de plus en plus d'attention à la sécurité et à la protection de l'environnement des matériaux d'intérieur des voitures.

Le problème de l'odeur doit être bien connu de tous, et l'incident du "cancer d'Audi" a donné un coup de semonce à toute l'industrie automobile, et je crains que COV les indicateurs deviendront la direction sur laquelle les constructeurs automobiles doivent se concentrer pour percer.

Dans l'incident "Audi cancer", nous reconnaissons le film d'arrêt des vibrations, mais en fait, plus que ces choses déclenchent, les indicateurs de COV dépassent la norme. Par exemple, l'intérieur de la voiture utilisera une variété d'adhésifs, tels que des adhésifs pour papier peint, des adhésifs pour tapis, des mastics, des adhésifs pour plastique, etc. Ils libéreront du formaldéhyde, du benzène, du toluène, du xylène et d'autres substances nocives.

Le liège est également presque inodore. Les produits fabriqués avec du liège ne produisent pas d'odeurs désagréables, et même lorsqu'ils sont carbonisés, il n'y a qu'une légère odeur de bois brûlé (plus comme du café, je pense). Le processus de laminage dépend davantage de l'adhérence des lipides du liège et des adhésifs naturels respectueux de l'environnement, qui sont presque inoffensifs pour l'homme. De plus, le cuir de liège transformé en un canapé confortable et chaleureux, plus important encore, n'émet pas d'odeur et ne stocke pas l'odeur.

Les consommateurs contemporains, en plus de l'accident d'apparence des performances du produit, prendront en même temps en compte l'utilisation de la sensation du produit, telle que le toucher, l'odorat, l'ouïe, etc. Comparé à l'odorat et à l'ouïe, le sens du toucher est un plus difficile à évaluer mais affecte vraiment l'utilisation de l'évaluation des caractéristiques. Dans la direction générale, la principale influence sur le sens du toucher est le matériau et le processus, tels que la texture du cuir se sentira mieux que le plastique ABS/PVC, le processus d'émail est meilleur que le processus de moulage par injection, l'ancien sentiment plus intime.

Ont rencontré un difficile d'expliquer la situation – deux produits utilisant le même matériau, le processus est en grande partie le même, mais la différence tactile est très différente. L'un est très intime au toucher et l'autre est très froid. Il est difficile de personnaliser la norme.

Cependant, le liège, qui se compose d'un grand nombre de coussins d'air microscopiques, est un matériau très confortable, tout cela grâce à sa structure cellulaire unique, le liège a une capacité unique à absorber les chocs et à soulager la pression sur les articulations et la colonne vertébrale, et se sent étonnamment doux au toucher, mais plus important encore : la température naturelle du liège est très similaire à celle du corps humain, contribuant ainsi à la sensation de confort. De plus, le liège n'absorbe pas la poussière, ce qui aide à prévenir les allergies.

Les pièces intérieures doivent non seulement être confortables et belles, mais aussi protéger la sécurité des passagers. À l'heure actuelle, de nombreux constructeurs automobiles utilisent beaucoup de plastique modifié élastique absorbant l'énergie et de mousse plastique pour réduire les dommages causés par les collisions sur le corps humain et améliorer la sécurité.

À cet égard, en raison de la structure en nid d'abeille du liège, il est capable de résister au frottement, aux chocs ou à l'usure. Lorsqu'ils sont soumis à une pression externe, les espaces dans les alvéoles du liège se rétrécissent et la pression interne augmente ; lorsque la pression est perdue, la pression à l'intérieur des cellules, dans les interstices, redonne aux cellules leur forme d'origine, ce que nous ressentons comme l'élasticité du liège ; la résistance du matériau découle de cette compressibilité et de cette élasticité - c'est le seul matériau qui peut être compressé d'un côté tout en conservant de l'autre son format d'origine.

Par conséquent, il est idéal pour être utilisé comme accessoire intérieur pour améliorer efficacement la sécurité.

Ont rencontré un difficile d'expliquer la situation – deux produits utilisant le même matériau, le processus est en grande partie le même, mais la différence tactile est très différente. L'un est très intime au toucher et l'autre est très froid. Il est difficile de personnaliser la norme.

Cependant, le liège, qui se compose d'un grand nombre de coussins d'air microscopiques, est un matériau très confortable, tout cela grâce à sa structure cellulaire unique, le liège a une capacité unique à absorber les chocs et à soulager la pression sur les articulations et la colonne vertébrale, et se sent étonnamment doux au toucher, mais plus important encore : la température naturelle du liège est très similaire à celle du corps humain, contribuant ainsi à la sensation de confort. De plus, le liège n'absorbe pas la poussière, ce qui aide à prévenir les allergies.

Liège et a un bon retardateur de flamme ; Flamme d'acétylène à 700 degrés brûlée pendant trois heures, et aucun dégagement de gaz nocif, pour atteindre le Niveau B2 de résistance au feu, avec des caractéristiques ignifuges.

En cas de rencontre malchanceuse avec un accident, le matériau en liège peut effectivement ralentir le temps de combustion et améliorer considérablement le temps d'évacuation.

Avec l'essor de la durabilité, les consommateurs sont de plus en plus sceptiques quant aux revendications écologiques des marques, ce qui rend difficile de déchiffrer leur véritable impact environnemental. Les consommateurs veulent que les constructeurs automobiles soient transparents sur l'impact de leurs inventions sur la planète et continuent de rechercher de nouvelles façons de produire des conceptions plus écologiques. Certains constructeurs automobiles investissent dans la recherche de nouveaux matériaux qui nous rapprocheront des véhicules à zéro émission. Les designs qui combinent cette nouvelle vision du luxe avec un design durable intelligent se démarqueront.

HZCORK travaille déjà avec plusieurs constructeurs automobiles et fabricants de pièces automobiles chinois, américains, allemands et japonais pour explorer davantage de possibilités pour le liège dans les voitures et accélérer le processus d'une révolution automobile durable.

Le liège a été utilisé dans les voitures il y a plus de 10 ans, mais à cette époque, il n'était pas très populaire en raison de divers problèmes. Au fur et à mesure que les temps avancent, je pense que le liège va bientôt épater l'industrie automobile.

Ci-dessous, je liste certaines des voitures les plus représentatives qui utilisent du liège.

La F700 a fait ses débuts au Salon de l'automobile de Francfort 2007 et représente la proposition de Mercedes-Benz pour une berline de luxe futuriste et écologique.

Avec sa voiture d'étude F 700, Mercedes-Benz redéfinit le concept de raffinement supérieur et décontracté : ce concept de la future voiture de tourisme de luxe montre comment une qualité de conduite supérieure peut être combinée avec un haut niveau de respect de l'environnement, de bonnes performances et une consommation de carburant extrêmement faible. .

L'équilibre et l'harmonie de la palette de couleurs sont le résultat d'une combinaison de cuir marron, d'Alcantara assorti et de liège à cellules ouvertes pour les garnitures de porte, le ciel de toit ou la console centrale, qui traverse tout l'intérieur. Les sièges sont recouverts de cuir beige avec de l'Alcantara assorti dans la partie centrale. l'aluminium peint peut être trouvé sur tous les panneaux de commande et SERVO-HMI.

Porsche a collaboré avec le designer et influenceur Sean Wotherspoon pour créer une voiture colorée sur le même thème. Basé sur Porsche Taycan 4 Cross Turismo, la voiture s'inspire du modèle Harlequin tout en poussant le concept d'un cran, empruntant même le thème pour l'intérieur.

Végétarien, Wotherspoon voulait s'assurer que l'intérieur de la voiture était sans cuir, il a donc utilisé du velours côtelé (un matériau déjà utilisé sur la 911 Targa Heritage Edition) et du liège (matériau tiré de l'écorce de chêne-liège) sur la garniture de toit, les sièges et le soleil. visières, ainsi que sur le tableau de bord, les montants, la console centrale, le volant et les tapis.

J'ai toujours qualifié les éléments en liège autour des fenêtres d'"arbres", selon Wotherspoon. Lorsque vous êtes dans cette voiture, vous avez vraiment l'impression d'être assis dans la nature. Vous avez le tapis vert qui représente l'herbe, puis vous levez les yeux et voyez la doublure de toit en velours côtelé beige Atacama. Vous avez également le tableau de bord et le volant en liège, qui semblent rustiques. J'aime être dans une voiture et avoir ce sentiment de l'environnement naturel qui m'entoure. Je n'ai jamais eu cette expérience dans une voiture auparavant, donc ça fait vraiment du bien de savoir que nous avons fait en sorte que cela se produise.

Le liège n'est pas le genre de matériau que l'on trouve dans une voiture de luxe, encore moins un multisegment de production. Mais Mazda est différent, car la société a inclus du liège à l'intérieur du multisegment MX-30. Ce matériau est obtenu à partir d'écorces d'arbres sans avoir à couper d'arbres, reflétant la conscience environnementale de la marque.

Le MX-30 est le premier modèle entièrement électrique de Mazda à présenter cette garniture en liège dans certaines zones de la console centrale, gracieuseté d'Uchiyama Manufacturing Corp. d'Hiroshima, au Japon. En fait, il est intéressant de noter que le prédécesseur de Mazda était Toyo Cork Industries, Ltd. et que la Mazda d'aujourd'hui ne peut s'empêcher d'être à nouveau associée au liège.

La MINI STRIP, un nouveau modèle officiellement lancé par MINI en association avec le créateur de mode britannique Paul Smith, a été conçue avec tous les détails astucieux sous une forme minimaliste. La simplicité, la transparence et la durabilité sont les thèmes centraux du processus de conception. Le panneau de garniture au-dessus de la console centrale et les panneaux intérieurs de la partie supérieure des portes sont en liège recyclé, qui ne contient aucun adhésif synthétique et est entièrement recyclable.

Dans une interview avec Oliver Heilmer, directeur du design de la marque MINI, il a déclaré : « À l'avenir, nous n'aurons plus besoin d'intérieurs en cuir car nous ne pensons pas que ce soit durable. Nous croyons également que même sans cuir, nous pouvons créer un produit moderne et de grande valeur »

Décorée dans deux tons de bleu ciel et de blanc nacré, cette Spiaggina est habituellement estivale, sans toit comme l'original et sans sièges arrière, puisqu'elle dispose désormais d'un compartiment décoré de liège et d'une douche intégrée, probablement destinée à enlever le sable après une journée à la plage.

Le modèle rend hommage au monde nautique, comme le pare-brise bas (presque inexistant) ou le design en liège qui recouvre l'arrière avec un motif qui imite les bateaux à plancher en teck utilisés sur le pont, les yachts. Il dispose également d'une barre anti-roulis blanche recouvrant l'appui-tête.

La Peugeot 208 Natural est une voiture d'origine 100% brésilienne avec un toit et un tableau de bord en liège. Les matériaux choisis assurent une meilleure isolation thermique et acoustique. Peugeot Brésil a présenté le véhicule au Salon international de l'automobile de São Paulo en octobre 2014 et novembre 2014, et il se distingue par l'utilisation de matières premières durables comme le liège. amorim Cork Composites était l'un des partenaires du projet, qui impliquait également Embraer Brésil.

Avec l'essor de la durabilité, les consommateurs sont de plus en plus sceptiques quant aux revendications écologiques des marques, ce qui rend difficile de déchiffrer leur véritable impact environnemental. Les consommateurs veulent que les constructeurs automobiles soient transparents sur l'impact de leurs inventions sur la planète et continuent de rechercher de nouvelles façons de produire des conceptions plus écologiques. Certains constructeurs automobiles investissent dans la recherche de nouveaux matériaux qui nous rapprocheront des véhicules à zéro émission. Les designs qui combinent cette nouvelle vision du luxe avec un design durable intelligent se démarqueront.

HZ CORK travaille déjà avec plusieurs Entreprises automobiles chinoises, américaines, allemandes et japonaises explorer davantage de possibilités pour le liège dans les voitures et accélérer le processus d'une révolution automobile durable.

Basé sur les nombreuses propriétés exceptionnelles du liège, le liège peut être transformé en tissus de liège, produits de sport en liège, sacs en liège, etc., qui sont considérés comme l'une des meilleures alternatives au cuir.

Choisissez les bons produits en liège pour promouvoir votre projet durable à faible émission de carbone.

Pour vous faire gagner du temps, nous avons également préparé des versions PDF de tous les catalogues de produits

Télécharger tous les produits au format PDF

Télécharger tous les produits au format PDF

Pour vous faire gagner du temps, nous avons également préparé des versions PDF de tous les catalogues de produits, ne laissez que votre e-mail et vous obtiendrez immédiatement le lien de téléchargement.

Contactez-nous pour obtenir un devis gratuit et plus d'expertise sur le tissu de liège. Votre projet rencontrera une bonne solution avec HZCORK.