Before answering this question, please let me tell you first what is cork fabric. In a short,

Cork fabric is a natural textile made from plant fibers. It is made from a strong layer of specific plant material, oak bark. The phellem layer of bark tissue is used to make cork, a versatile and impermeable material.

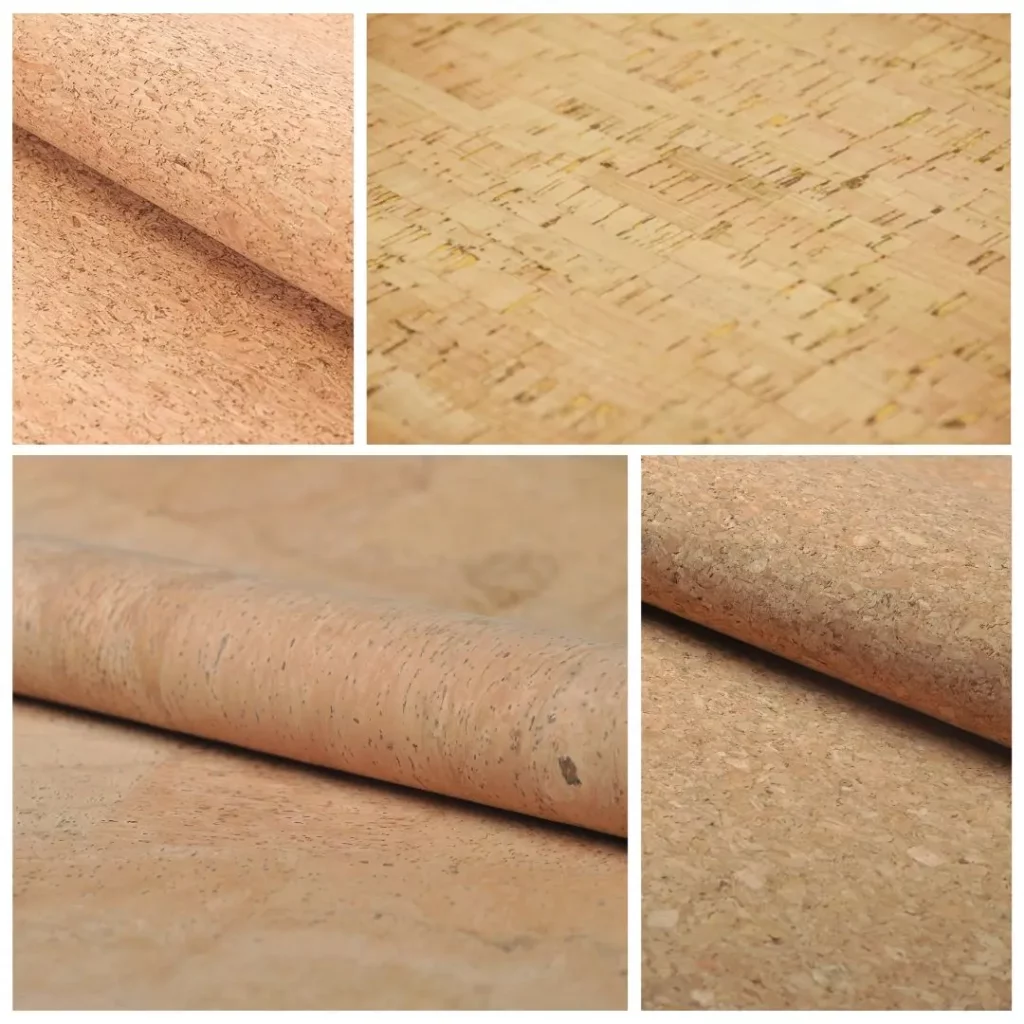

Cork fabrics are textiles made from plant fibers harvested from oak trees. The cork fabric then adheres to a textile backing, which is usually backed with other natural fibers such as cotton, linen and flax. The most sustainable backing fabrics are organic and made from cotton, linen or hemp. This sustainable resource is fantastic in terms of functionality and energy efficiency.

Cork fabric is a natural textile that is widely used in high fashion. It is very soft, comfortable, lightweight, long-lasting and durable. It is a material that can be found in many everyday garments, bags and accessories, making it a more responsible choice.

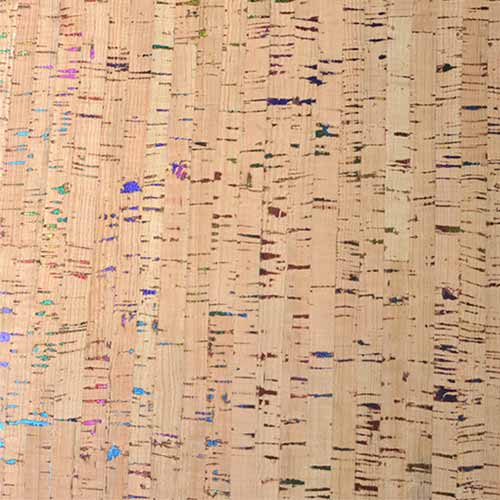

Cork fabrics for sewing can be easily dyed, cut and sewn into a variety of styles and patterns. They come in many types of cork fabrics in a variety of sheens and colors.

That’s why cork is an eco-friendly fiber that is perfect for sustainable fabrics and fashion textiles. It is a natural, durable, 100% biodegradable, compostable and recyclable material.

Cork products benefit the natural and human environment in many ways. They help generate income for artisans and weavers in local communities.

So maybe you will be curious about what is cork?

So what is cork?

As mentioned of cork, the first impression in most people in the world is the cork stoppers in red wine. Because cork has great features that can be widely used as a stopper: impermeable and moisture-resistant, compressible and antimicrobial. But do you know why cork has those features? And what is real cork?

Cork is mainly made from the bark of the cork oak (Quercus Suber) which is grown in sunny and warm countries like Spain, Portugal, Italy, France, Algeria, Morocco and Tunisia. Globally speaking, Portugal is the biggest producer of cork. If you’ve ever traveled to the rural areas of Southern Portugal — where most of the world’s cork oak trees are grown, you will see how cork tree was planted and harvested.

Generally speaking, newly planted cork oak trees take, on average, more than 25 years of growth before their bark can first be harvested. Cork oaks can live up to 250 years and produce between 50 and 100 kg cork in each harvest. Very old and large cork oaks can even yield between 500 and 1300 kg in just one harvest. What is rarely known by most people is that the tree can generate back per eight or nine years. Once the barks protective layer has been peeled, it will regrow silently until it has become plump and thick next time.This fabulous oak is the only tree that will not be damaged by removing the bark. Instead, it is a respected growth period so that the cork gets the nutrients it needs, peeling off the bark is actually good for the Quercus Suber as it means it can absorb three times as much CO2 than an “unpeeled” tree. Just like the kids, we need to have some patience to wait for them to grow up. The plant, in itself, is a miracle.

From cork harvest to cork fabric manufacturing-a long process

The first peeling is also known as “virgin bark”. Virgin bark is rough, uneven, and rich in resin, which is why it is usually used for cork insulation panels or granulation. Peeling the cork bark of the tree is done manually with special cutting axes; it needs to be done carefully in order to avoid damaging the “mother layer”. Both the trunk and the main branches are de-barked; this occurs during the warm summer months when the bark is easier to remove.

After the peeling process, the harvested bark is sorted and stacked in storage areas in the cork oak forests/plantations or close to the cork factories. It is dried in the open air for at least 6 months to guarantee excellent air circulation. After the drying process, the bark is steamed on stainless steel panels to straighten the naturally rounded shape.

This process takes another 6 – 9 months.

As an anti-bacterial treatment, the cork is then boiled. This increases the elasticity and volume of the material and decreases its density. The boiling water is used as a natural fertilizer. After cooling down and drying for a second time, the cork needs to stabilize for about two weeks to decrease the humidity to a degree that makes further processing possible.

Then all the cork raw material was trimmed to be regular shape like this and stored pallet together.

The cork material will be divided into various levels of quality and can be then taken to production sites, for instance, to make cork fabric to cork wallpaper. Only materials of quality levels A and B are suitable for cork fabric and wallpaper production; level C cork is used for granule flooring and insulation. Cork harvest and production are subject to stringent government controls and detailed requirements by the European Cork Association, which must be adhered to. Some thick enough cork sheet material was used to do a wine stopper, which is punched out of the bark.

We usually buy the material by containers, each level quality in a different container, packed like this.

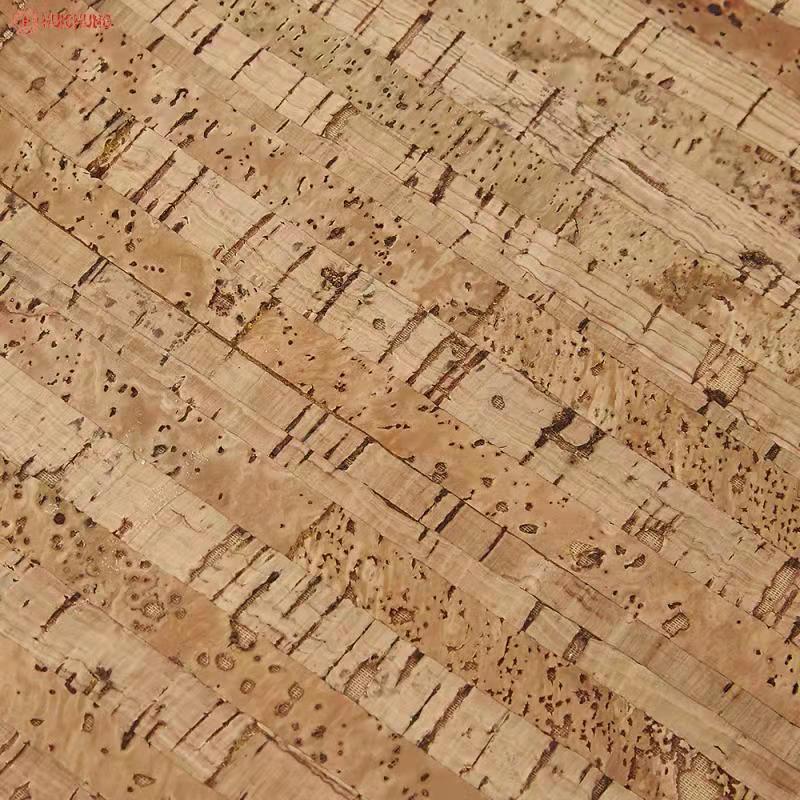

As you can see in below picture, our bread vein コルクレザー生地 was made by high-quality grade A raw material, which have fewer bugs and stain:

The slub pattern cork fabric in grade B with bigger bugs:

Grade C has bigger bugs, color not so clean:

Grade D have obvious bugs and stains, color was darker:

The leftover material, or post-industrial waste, is boiled and ground up, then compressed using adhesive resins. Our resin is food-grade quality, and eco-friendly.

The last process is to adhere the thin cork sheets to a fabric support backing. We have many different backing bases, including cotton, polyester, or poly-cotton, depending on where did you use it.

Why cork fabric?

Cork fabric has exceptional characteristics, which make it perfect to do bags, wallets, upholstery wallpaper, and flooring.

Stain resistant

One of the characteristics of cork fabric is its stain resistance. Unlike other materials, cork easily removes stains that may be picked up throughout use. A quick wash with water and soap is all that is required.

耐水性

The water resistance of cork is one of the best properties of this material and plays an important role in how it has become such a durable fabric. Cork has a waxy substance called corkiness covering its cells, and it is this substance that helps repel water, thus extending the life of the product.

Lighter

Hold a wine cork and you’ll know it’s very light. Cork weighs only 0.16 g/cm3. Over 50% of the components of the cork are a mixture of gases almost identical to air, making it light enough to float on water.

耐久性

The honeycomb structure of cork also allows it to resist scratches that may be caused by friction, impact or abrasion. This is another reason why cork is used as an industrial material.

Flexibility and Compressibility

The air-like mixture of gases in the confined cells gives cork its elasticity and compressibility.

The cork retains its elasticity even when compressed to half its volume, and once decompressed

Once decompressed, it immediately regains its original shape.

Thermal and acoustic insulation

Cork contains nearly 40 million cells per cubic centimeter, which effectively absorbs noise, making cork an Excellent sound and vibration insulator.

Cork is an excellent acoustic and vibration-resistant material. The molecular structure of cork allows it to absorb and store heat for long periods of time.

time to store heat.

Flame and fire-resistant

Cork is not easily combustible and is a natural fire retardant and fire barrier. Cork burns without flame and does not release toxic gases.

Anti-static and anti-allergic

Cork does not attract dust and prevents the breeding of mites, thus helping to prevent allergies.

What is cork used for?

Cork fabric can be used for a wide range of products, from fashion accessories to home décor. Here are some of the most common uses for cork fabric.

コルクバッグ: cork fabric is a popular material for bags including purses, totes and backpacks. It is environmentally friendly, lightweight, durable and waterproof, making it one of the perfect alternatives to animal leather bags.

コルクシューズ: Cork leather is also used in the production of shoes, particularly insoles and footbeds. It is comfortable, breathable, and provides good support, making it a great option for people who spend a lot of time on their feet. Read more: Cork Shoes: The Definitive Guide

Cork Jewelry: Cork leather can be used to make a variety of jewelry, including bracelets, earrings, and necklaces. Its natural texture makes it a popular choice for handmade jewelry.

Cork Mats: Cork leather can also be used for home décor such as coasters, placemats and table runners. Its waterproof and easy-to-clean properties make it ideal for kitchens and dining rooms.

コルク家具: cork leather is also used to make furniture such as chairs, sofas and stools. Cork leather is becoming one of the best material choices for designers due to its natural environmental properties and excellent durability and waterproof physical properties. Read more: The ultimate guide to cork furniture

コルクヨガ: Cork yoga mats are in line with yoga practitioners’ pursuit of a back-to-basics, rustic and natural look, and they are non-toxic, odorless and soft to the touch, favored by many yogis.

Cork flooring: Cork leather has a long history of being used as a flooring material. Cork leather’s natural texture and soft touch, durability and fire resistance make it a popular choice for creating unique and stylish floors. Read more: How To Choose Cork Flooring

Cork Building: Architects have chosen cork for its unique properties in terms of thermal and acoustic insulation, as well as its texture, malleability and lightness, resulting in famous buildings such as the Portuguese Pavilion at the World Expo in Shanghai, China and the Google Store in New York. Read more: Top 10 Cork Building Designs

Cork car interiors: you read it right, cork has been applied to automobiles, such as roof lining, car cushions, car feet, etc. Not only does it meet environmental standards, but also reduces the weight of the car, which is a trend. Read more: 自動車内装革命: 持続可能なコルク

Environmental Advantages of Cork Fabric

Reduced Carbon Footprint.

Cork oak forests act as carbon sinks, absorbing and storing carbon dioxide from the atmosphere. According to the Forest Stewardship Council (FSC), cork oak forests have five times the carbon sequestration potential of non-cork forests. By using cork leather instead of traditional leather, up to 24 kilograms of carbon dioxide can be reduced per square meter of leather produced. According to the study, cork oak forests could sequester 14.5 million tons of carbon dioxide per year, equivalent to the annual emissions of 3 million cars.

Conservation of biodiversity.

Cork oak forest ecosystems are home to a wide variety of plants and animals, including endangered species such as the Iberian lynx and Barbary macaque. Maintaining these forests is vital to preserving biodiversity. Cork oak forests are one of the world’s 35 biodiversity hotspots.

Water conservation.

Cork leather production requires very little water compared to traditional leather production, which can consume up to 20,000 liters of water per kilogram. In contrast, cork leather production requires only a fraction of this amount, as the cork oak tree absorbs water from the soil and does not need to be irrigated. In fact, Portugal’s cork oak forests, which produce more than 50% of the world’s cork, have a water footprint 10 times lower than that of non-irrigated farmland.

Durability and recyclability.

Cork leather is a durable material that can last for many years, reducing the need for frequent replacement. Cork leather is made from by-products of the cork industry that would otherwise be discarded, and by using this material, waste is reduced and a circular economy is promoted. And cork leather is biodegradable and can be easily composted at the end of its life, unlike synthetic leather made from petrochemicals.

Durability and recyclability.

Cork leather is a durable material that can last for many years, reducing the need for frequent replacement. At the end of its useful life, cork leather can be recycled or biodegraded, further minimizing its impact on the environment.

Economic benefits of cork

- The global cork industry employs approximately 30,000 workers in a variety of jobs, from harvesting to refining. (Cork Quality Council)

- Portugal has about 737,000 hectares of forests, more than a third of the world’s cork oak forests. From this land, Portugal produces about 100,000 tons of cork annually, half of the world’s cork production. (Cork Quality Council)

- Spain is another major world producer of cork products. They produce 62,000 tons of cork annually, or 31% of the total production from 574,000 hectares of forest space. (Cork Quality Council)

- 72% of all cork revenue generated by the industry comes from wine cork. The total market value is estimated at €644 million per year, representing 25% of total Portuguese production. (Cork Quality Council)

- Cork construction materials account for 25% of the total value of the Portuguese industry, valued at €228 million. (Cork Quality Council)

- Only 1% of the cork market is used for raw material exports. (Cork Quality Council)

- The cork industry produces more than 13 billion wine corks per year, including corks and champagne corks. (Cork Quality Council) #8.

- growth in the global wine market has fueled a 7% annual growth in the global cork market. in 2010, the US cork market was valued at €64.1 million. in 2015, it was valued at €103.2 million (Cork Quality Council). (Cork Quality Council)

- the estimated value of each hectare of cork oak forest is €100 per year, directly attributable to environmental services. (Portuguese Cork Association)

- globally, cork forests are capable of removing about 14 million tons of carbon dioxide from the atmosphere. (Portuguese Cork Association)

- up to 135 different plant species can be found per square meter in a typical properly managed cork forest. (Portuguese Cork Association)

- 80% of the companies involved in the cork industry are in Portugal. 49% of these organizations specialize in the production of cork. (Portuguese Cork Association)

- 81% of companies active in the cork industry reported positive net income in 2016. The average turnover was only 2.5%. (Portuguese Cork Association)

- In Portugal, on average, more than 40 million cork stoppers are produced every day. (Portuguese Cork Association)

- The Portuguese cork industry has 691 registered patents. This has helped the industry to achieve a 63% export share in the cork sector. (Portuguese Cork Association)

- Cork debarking is the highest-paid job on average in the agricultural sector. That’s because it requires an extremely high level of expertise to do correctly. The average salary starts at 45,000 euros per year. (Amorim / Payscale)

- The cork oak tree is able to regenerate its outer layers about a dozen times throughout the life of the tree. The average lifespan of a tree is about 150 years, but some trees can live for more than 350 years. This means that a tree can be harvested every 10 years or so after the initial harvest, which can take up to 20 years. (Cork Institute of America/Green Building Supply)

- The bark tissue harvested from cork oak trees has a very low density. This is because about 90% of the tissue in the bark is gaseous. Very dense cork products may only have a density rating of 0.20. (Green Building Supply)

- In 2005, Wine Spectator tested 2,800 bottles of wine for trichloroanisole (TCA), of which 7% were found to be contaminated. All it takes is one bad bottle of wine from a bad cork to damage a winemaker’s reputation. However, since 2001, testing by the Cork Quality Council has shown a 95% reduction in TCA. (Atlantic Organization)

- 20 The major threat to the wine industry, especially for cheaper wines, is the aluminum screw cap. About 20% of table wines sold in the world today have switched from cork to aluminum caps. (Atlantic Organization)

- Plastic caps are also beginning to penetrate the cork market. For wines priced under $10, the cork industry may have lost 40% of its cap market share. (Atlantic Organization) #22.

- In 2010, 168 bottles of Champagne were found in a shipwreck in the Baltic Sea. Although Champagne is 170 years old, it is still drinkable due to the quality of the cork. (Atlantic Organization)

- Morocco’s small cork industry provides only 6% of global cork production from 383,000 hectares of cork forests and supports the local economy with more than $11 million annually. (Atlantic/Cork Quality Council)

- 24 In total, more than 100,000 people are directly or indirectly supported each year as a result of the global cork industry. (Atlantic Organization)

- Tunisia, France and Italy each account for 3% of the total production of the cork industry. Together they produce 18,000 tons of cork annually. (Cork Quality Council)

So, we can summarize cork fabrics as:

- No waste is generated during extraction, processing or production

- No additives, tanning or finishing substances are used to process raw cork into cork leather

- Fully recyclable; can be milled into new materials

- Beneficial to soil and air quality in and around cork forests

- Cork forests sequester 14.7 tons of CO2 per hectare

- Creates homes for thousands of rare/endangered plants and animals

- Grows in Mediterranean countries, mainly Portugal

- Workers love their work; no risk to the health and safety of workers or community members

As we’ve told you many times, cork has all the qualities and attributes that cork oak forests offer us, and all that we do to make the world a better place, with added value that money can’t buy.

Contact HZCORK today for more details on cork fabrics that can help you boost your business!