Leather has a long history of use, it is widely used in the fashion world for all types of clothing and accessories and is also widely praised for the longevity and durability of its material. However, although leather is still seen as a luxurious, chic product, it is not without its drawbacks. The more I learn about modern leather production, the more I can see how great this disadvantage is.

Cork, on the other hand, is much less well-known and sometimes misunderstood (mistaken for plastic leather). However, in terms of its material properties, it is the equivalent of vegetable-based leather, without the animal abuse involved in leather production.

I therefore compare the differences between cork leather and leather in all aspects: raw materials, processing, properties, applications, industry trends, and the environment. The discussion starts with the raw material stage and moves from production to the final product.

Definition of leather: hides that have been stripped directly from animals without processing are called raw hides, also known as rawhides.

Types of leather: including cowhide, pigskin, sheepskin, snakeskin, horse skin, ostrich skin, crocodile skin, lizard skin, etc., of which cowhide, pigskin, and sheepskin mainly account for more than 90%.

Nowadays, leather is not only a by-product of the meat and dairy industries but also due to the growing human demand for leather products, animals are killed in order to produce it.

According to PETA, “Most leather produced and sold in the United States is made from the skins of cattle and calves, but leather is also made from sheep, lambs, goats and pigs. Other species are hunted specifically for their skins, including zebras, bison, kangaroos, elephants, crocodiles, alligators, ostriches, lizards, and snakes.” Too many exotic animals are killed because many people can’t live without leather. Given that leather gives the wearer a sense of style, sophistication, and wealth, consumers should start looking for alternatives that cost less and look and feel similar to leather.

Cork leather comes from the bark of the cork oak tree and is considered one of the most sustainable forestry practices on the planet. The cork oak tree is never cut down and usually lives to be 100 to 300 years old. The cork is harvested from the bark, which helps to support the growth of the tree and the uptake of CO 2.

In fact, harvested cork trees absorb three to five times more CO2 than unharvested trees. Cork oaks in Portugal alone help to offset 10 million tonnes of carbon each year. Cork trees are also important producers of oxygen. Cork leather is not only the most natural and durable ‘vegan leather’ on the market today, but it has all the benefits of animal leather without cruelty and pollution.

Cork grows in countries around the Mediterranean, namely Portugal, Spain, Italy, France, Algeria, Tunisia and Morocco, and enriches the soil and livelihoods of all these countries. Cork forests absorb thousands of tonnes of carbon dioxide every day, provide watersheds and root systems, feed the soil, produce oxygen, and are home to countless species of flora and fauna that are often endangered or do not exist anywhere else in the world. The cork forests contribute to the natural beauty and purity of the Mediterranean.

The leather undergoes stages of processing in the finished product such as salt wet leather, blue wet leather, billets and finished products, and later on, it is made through various processes called leather.

Many factories have been exposed to cruel debarking procedures, where the hides are removed straight away while the animal is conscious, which I believe is not something we are happy to see. Whatever the brand, if the leather is used, it can increase in value. However, ostrich skins are only used by young birds under 14 months of age, otherwise, the leather will become old and feel poor; crocodile skins are only used from the soft belly of three-year-old crocodiles, simply because young crocodiles are less likely to leave scars on their bellies.

Freshly removed animal skins need to be effectively cleaned by immersing them in water mixed with chemicals, as there is still feces and dirt on the surface; after cleaning they need to be soaked in solvent to make the leather more durable; in addition, the leather needs to be chemically preserved, with at least a dozen toxic substances. Studies have shown that leather workers in Switzerland and Italy are 20 to 50% more likely to develop cancer than normal.

To add insult to injury, the complex composition of industrial effluent from tanning and fur processing makes it difficult to treat the effluent, thus causing ecological pollution. The US Centers for Disease and Prevention also reported that residents living near a tannery in Kentucky were five times more likely to develop leukemia than the national average.

The cork oak tree can live up to 250 years and can produce 50 to 100 kilograms of cork per harvest. Cork oaks are never cut down and harvesting them does not harm them as it is the “dead skin” that is stripped off the surface of the oak and instead helps to support the growth of the tree and the absorption of CO 2. In fact, harvested cork trees absorb 3-5 times more CO2 than unharvested trees. Cork can regenerate every eight or nine years. After the protective layer of bark is removed, it grows back silently until it is plump and thick next time.

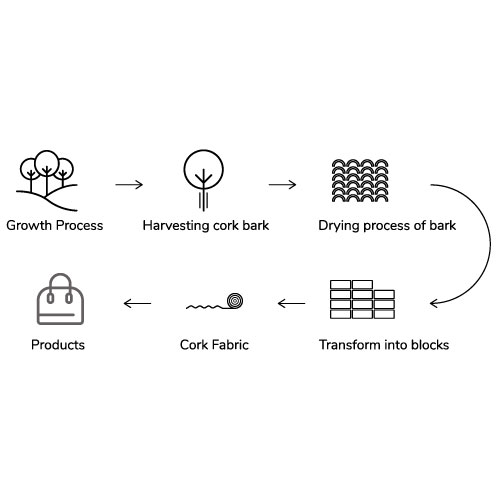

After the debarking process, the harvested bark is sorted and stacked in a storage area near a cork oak forest/plantation or cork mill. It is dried in the open air for at least 6 months to ensure good air circulation. After the drying process, the bark is steamed on stainless steel plates to straighten its natural round shape. This process takes a further 6 to 9 months.

As an antibacterial treatment, the workers boil the cork. This process uses water several times and does not consume large amounts of water, which increases the elasticity and volume of the material and reduces its density, the boiling water is used as a natural fertilizer. After the second cooling and drying, the cork needs to stabilize for about two weeks to reduce the humidity to a level where it can be processed further.

The cork leather is made from these processed cork woods which are glued to the backing in thin slices using specialized techniques. The gluing of the cork can be done by heating, as the cork comes with a natural glue called “cork fat” which is strong enough, or by using other natural resins depending on the process. Cork leather is produced without chemicals.

The cork waste from the process is recycled and, through screening, can be turned into fertilizer, pellets, etc. The utilisation of cork can be close to 100%.

Leather surface:

With genuine leather, you will notice that the surface structure is not completely uniform. It will often have scars, blemishes and other defects. This is because it is made from animal skins. Genuine leather is a natural material. Therefore, when you run your fingers over it, it will not feel very smooth. Press your fingers into the leather – the surface will stretch and wrinkle like skin.

Smell: Leather has a distinctive ‘leather’ smell – it has a natural organic skin smell that cannot be accurately manufactured.

Physical properties.

Water resistant

Leather can be made to absorb water, resist water or be completely waterproof. Most leathers made for the footwear, bag, upholstery and leather goods industries offer a degree of water resistance that allows the leather to retain its elasticity and shape after drying when it gets wet.

Thickness

Leather produces thin leathers for bindings, gloves, linings and garments, which have excellent softness.

Hides can be made in a wide range of thicknesses because they can be layered. Different thicknesses are used to produce different leather products.

Softness

The softness of leather is usually related to its thickness. The thinner the leather, the softer it will be. But there are other variables that make the leather softer, particularly the type of tanning: chrome tanning is generally softer; aldehydes are softer and vegetable-tanned leather is harder.

Absorption and desorption (release of absorbed water)

This is one of the unique characteristics of leather that allows it to absorb moisture and release it into the environment over time. The leather can retain large amounts of moisture without feeling damp, so the feet remain dry and comfortable without the chill that comes from quickly evaporating or cooling sweat.

Water vapour permeability

Often referred to as ‘breathability’, this property allows moisture and air to penetrate the leather. Waterproof leather is designed to maintain breathability while providing protection from wet conditions.

Aesthetics and surface patterns

There are many variations in the colour, texture, feel, smell, surface resistance and feel of leather, making this product very unique and valuable.

Thermal insulation

One of the main reasons why leather is so comfortable on human skin is its great ability to insulate. Insulation is a measure of the rate at which heat passes through the material. And because leather contains a lot of air (which is a poor conductor of heat), heat travels very slowly through the material.

Ductility

Another factor that makes leather such a popular material is its ability to be moulded into new shapes. It can be hardened or softened and retain its new shape as required.

With its soft texture and natural grain surface, cork leather is often compared to fine leather. Cork leather is flexible, generally reverts to its original shape on impact and is very light. The smoothness of cork also makes it ideal for many products – it feels great on the skin.

Odour: Cork leather is essentially odourless, or has a faint woody scent.

Physical properties.

Stain resistance

One of the characteristics of cork fabrics is their resistance to stains. Unlike other materials, cork can easily remove stains that may have been picked up during use. A quick wash with water and soap is all that is required.

Water resistance

The water-resistance of cork is one of the best properties of this material and plays an important role in how it has become such a durable fabric. Cork has a wax-like substance called cork that covers its cells and it is this substance that helps to repel water, thus extending the life of the product.

Lightweight

Cork weighs just 0.16 g/cm3. over 50% of the cork is a mixture of gases almost identical to air, making it light enough to float on water.

Durable

The honeycomb structure of cork also makes it resistant to scratches that may be caused by friction, impact, or abrasion. This is another reason why cork is used as an industrial material.

Flexibility and compressibility

The air-like gas mixture in the closed pores gives cork flexibility and compressibility. Cork retains its elasticity even when compressed to half its volume and once decompressed, it immediately regains its original shape once decompressed.

Thermal and acoustic insulation

Cork contains nearly 40 million cells per cubic centimetre, which effectively absorbs noise, making it an excellent sound and vibration insulation material. Cork is an excellent sound and vibration insulating material. The molecular structure of cork allows it to absorb and store heat for long periods of time.

Flame and fire-resistant

Cork is not easily combustible and is a natural fire retardant and fire barrier. Cork burns without a flame and does not release toxic gases.

Anti-static and anti-allergy

Cork does not absorb dust and prevents mites from breeding, thus helping to prevent allergies.

Easy to clean

Thanks to their impermeability, cork products are very easy to clean. All that is needed is a damp cloth and a pH-neutral detergent (e.g. soap) to do the job. No matter how many times the product is washed, the quality and beauty of the cork are assured.

Resistant to decay and chemical attack

Cork is not chemically resistant to water, grease, petrol, organic acids, salts and esters, in addition to being resistant to the effects of concentrated nitric acid, sulphuric acid, chlorine and iodine.

Leather can be used to make a variety of items including clothing, footwear, handbags, furniture, tools, and sports equipment, and can last for decades. Tanning has been practiced for over 7,000 years.

As well as being used in areas where leather is used, cork is also of essential importance in industry, construction, and aerospace.

Ideal as a sealant for various applications in the automotive and electrical industries.

Cork is often the first choice for the construction industry due to its ability to act as thermal insulation, sound insulation, and damper at the same time. Cork is non-corrosive, fire-resistant, and can withstand heavy loads. It is widely used as insulation for roofs, walls, floors, and ceilings.

Probably the most prominent development of cork is in the aerospace industry, as part of protective heat shields in missiles and spacecraft.

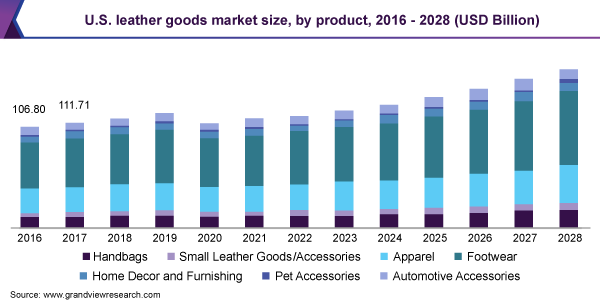

The global leather market is expected to grow at a CAGR of around 6.0% over the forecast period 2021 to 2028, reaching US$ 626.1 billion by 2028.

Increasing consumer demand for comfortable, stylish, and fancy goods, high spending power, and changing fashion trends are the main factors increasing the demand for leather products, which is driving the growth of the global leather market. High spending power and leather products, such as shoes and bags, are witnessing high demand. The availability of large quantities of raw materials is enabling manufacturers to focus on providing consumers with high-quality products.

The US meat industry generated 31.1 million hides and skins in 2016, as well as 4.4 million pig skins and 2.3 million goat and sheep skins. The leather industry buys these hides and skins. The country’s growing cattle waste and the high priority given to waste management, combined with favourable business policies for the leather industry, will witness high demand for products made from leather.

According to the report, the global market for vegan leather (including mushrooms, pineapples, cork, leftover fruit, etc.) is expected to grow at a CAGR of 48.1% during the forecast period 2020-2026. By 2025, the market for vegan leather will be worth US$89.6 billion.

Geographically, North America holds the largest share of the global vegan leather market. In addition, Europe is the second largest market for vegan leather due to the increasing demand for animal-free and environmentally friendly alternatives. The European region offers huge market growth potential due to the rapid growth of markets such as the UK and France.

Asia Pacific holds a significant share of the vegan leather market due to the rapid growth of markets such as China, India, Japan and South Korea. China is the largest market for vegan leather in the Asia Pacific region.

More information: Why Cork Vegan Leather Project Could Be Profitable In The Next 10 Years

The demand for leather is growing. Over 22 billion square feet of leather is produced each year, roughly the size of a small country. By 2030, it is estimated that this will reach 30 billion square feet per year.

Up to 80% of deforestation in the Amazon rainforest is linked to cattle farming. This deforestation leads to massive biodiversity destruction, which in turn endangers native plant and animal species. Another major driver of deforestation is soy production, which is also closely linked to leather. Approximately 80% is used as feed for cattle and other farm animals. 77% of the world’s agricultural land is used to raise animals for slaughter and to grow fodder for them.

Leather production is also water-intensive. Some estimates suggest that over 17,000 liters of water may be required to make a single cowhide handbag. Leather production not only consumes water but is also polluted. Leather is transformed into leather through the tanning process, 90% of which is tanned with carcinogenic chromium and often with formaldehyde and arsenic. Leather facilities contribute to air pollution through water pollution caused by organic solvents (VOCs) used in the disposal of animal carcasses, solid waste known as rawhide waste, and wastewater discharged from the facilities.

In 2015, the global annual impact of the leather industry was estimated at 130 tonnes of CO2 equivalent (carbon dioxide equivalent) – the equivalent of roughly 30 million passenger cars!

Put another way, the total carbon footprint of a pair of leather shoes (approximately 1.7 square feet of leather) is equivalent to approximately 10 kg of CO2 emissions, including upstream, manufacturing and downstream production stages.

The vast majority of the leather industry’s greenhouse gas emissions come from rearing animals. Methane, nitrous oxide and carbon dioxide produced by cattle account for a staggering 14.5% of total global greenhouse gas emissions – more than all transport systems combined.

Cork forests are one of the world’s 36 biodiversity hotspots, alongside the Amazon rainforest, the African savannah, the Andes, and Borneo. Cork forests provide ideal habitat for more than 160 species of birds, 24 species of reptiles and amphibians and 37 species of mammals, some of which are endangered, such as the Iberian lynx, the world’s most endangered feline.

The cork forests are deservedly the lungs of the planet, absorbing 14 million tonnes of CO₂ per year, helping to mitigate global warming, prevent land desertification, reduce soil erosion and regulate the water cycle.

In addition to its high biodiversity, Montador plays an important role in regulating soil and water conservation, preventing wind erosion and increasing the rate of rainwater infiltration and groundwater recharge. Considering that cork oaks intercept about 26.7% of total rainfall, they also reduce runoff and thus prevent soil erosion.

Each cork can absorb 112 grams of CO2 on average.

Each ton of cork can absorb 1.83 tons of CO2

Making a plastic bottle stopper emits 10 times more CO2 than a cork.

The manufacture of an aluminum screw cap emits 24 times more CO2 than a cork.

Studies show that for every ton of cork produced, cork oak forests can sequester up to 73 tons of CO2, thus helping to reduce global warming potential.

Portugal’s cork oak trees alone – about one-third the size of Mediterranean cork oak forests – can absorb 4.8 million metric tons of CO2 per year, which according to the U.S. Environmental Protection Agency proves is equivalent to the emissions of more than 830,000 passenger vehicles per year.

More information: The Best Of The Low Carbon Economy – Sustainable Cork

More than 100,000 people in seven Mediterranean cork-producing countries benefit directly or indirectly from the development of the cork oak forest economy.

Leather has a long history and unparalleled appeal, but it is unforgivable to maim animals and pollute the environment simply for the love of man. Cork is as durable as leather, has the same estimated lifespan and has very similar aesthetic qualities such as a smooth, shiny and soft texture.

Whether you are looking at it from an environmentally conscious and sustainable point of view or simply looking for beautiful, high quality, durable and long-lasting bags, purses and accessories, cork is nature’s solution.

There is no doubt about the pursuit of sustained economic growth and its significant impact on our environment and society. Globally, awareness of the need for sustainable development is growing and the principles of sustainable development are entering national and international policies. As the population continues to grow and we all seek to improve our environment, creating significant additional demands on resources, sustainability becomes a key focus of any and all design more important and necessary than ever.

Based on the many outstanding properties of cork, the cork can be made into cork fabrics, cork sports products, cork bags, etc., which are considered one of the best alternatives to leather.

Choose the right cork products to promote your low carbon sustainable project.

To save you time, we have also prepared PDF versions of all product catalogs

Download all products as a PDF

Download all products as a PDF

To save you time, we have also prepared PDF versions of all product catalogs, only leave your email and you will get the download link immediately.

Contact us to get a free quote and more expertise about cork fabric. Your project will meet a right solution with HZCORK.